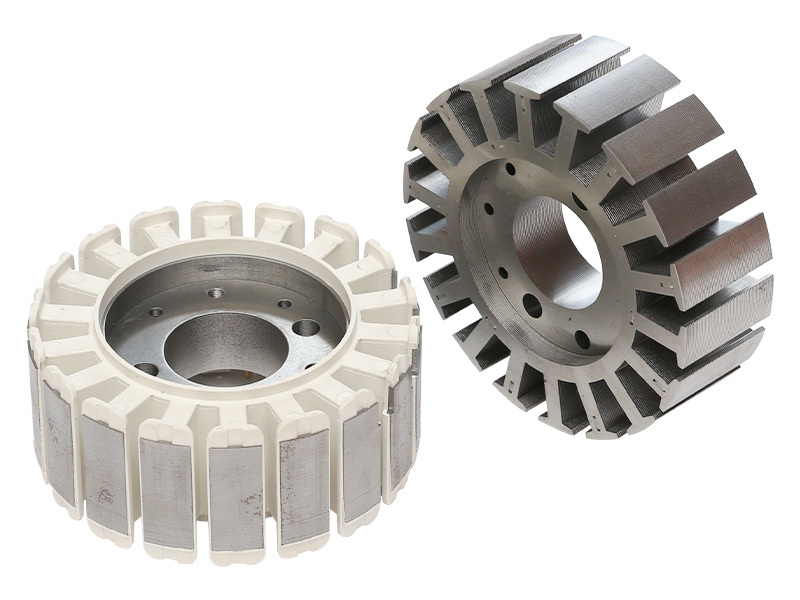

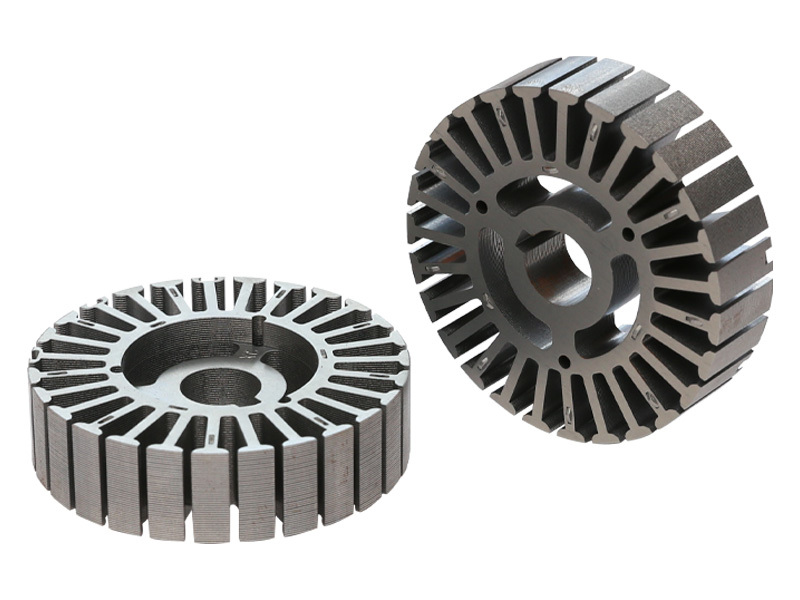

Stamping progressive die manufacturer: motor stator punching sheet die

2023-01-04

The stamping progressive die manufacturer tells you that the shape of motor stator punching dies is generally forged from round steel to meet the rough requirements of its required dimensions. Ordinary Cr12 type steel, Cr12MoV or CrWMn type steel is used for motor stator punching dies. After forging, it can improve the crystal carbide unevenness of steel, crush large carbide, refine carbide, reduce bias, meet the requirements of grade 2 carbide, improve the process performance and use performance of Cr12 and other types of steel, and prolong the service life of the die.

Cr12 steel for motor stator punching dies has low thermal conductivity and poor plasticity. When heated, the temperature difference between the surface and the middle generates temperature stresses and the critical point generates tissue stresses, which will lead to core rupture of the material. In addition, there are many forging crack defects due to the narrow range of heating and forging temperatures for these materials.

After forging Cr12 round steel into square die blanks, parallel cracks tend to appear in the middle of the two opposing planes of the rectangular body, typically 10 ~ 1 ~ 3 mm long, 1 ~ 3 mm short, and about 5 mm deep. This phenomenon is observed that the more uneven the crystal carbide is, the longer the crack length is, and the crack will be terminated when there are few crystal carbide particles.

The reason for the motor stator punching die: the crystal carbide segregation in the steel is very severe. This high chromium, high carbon Leyland bulk steel has a large amount of excess carbides and large segregation, which reduces the strength and toughness of the steel.

When initially forged, the hammer is too heavy and the forging direction is incorrect and limited to radial forging. When the deformation is too large, cracks appear first in the middle of the round steel, i.e. in the area with little austenite and a large number of crystalline carbide bodies. The strength of a high temperature forged billet is much higher than that of a high temperature austenitic billet with better plasticity. Cracks appear in austenite with very small widths, which are difficult to find and fill with oxide after forging. Cracks are found in the middle of the rectangular body relative to the plane when the motor stator punching die blank is cooled to room temperature.

01-04

Carbon fiber tube winding mold forming process

Carbon fiber tube production process is one of the more mature production methods, the quality of carbon fiber tube products made by this process is better than other processes.

01-04

Precautions for daily use of the stator

The daily use of the stator winding machine has been a headache for people, then Taizhou Yangnuo Mould Co. First, the structure of the stator and rotor Stator winding machine is simple and convenient, and can be used for punching and cutting tensile test pieces and other test pieces of various shapes.

01-04

So independent suspension must be independent? Some multi-links are not purely independent suspensions if strictly differentiated as required. Because the independent suspension is based on the fact that the two wheels operate independently and do not interfere with each other, but in some models, in order to prevent the lateral displacement of the independent suspension, a lateral stabilizer bar is added between the two wheels.

01-04

Top ten common brake system failures and solutions

Whether the brake system is fault-free or not directly determines our life safety. Its performance cannot be determined because the production design has been fixed. We must ensure that it can operate normally without failure. So what are the faults that the brake system often causes? What are the symptoms when you brake?